6 Things You Need To Know About Cooling Tower Fill Media Today

Date:

Category: Blog Views:

Table of Contents

1. What is the fill in a cooling tower?

2. Types of cooling tower fills

3. Cooling tower fill function

4. Cooling Tower Fill Principles of Operation

5. What is the purpose of fill in a cooling tower

6. How to choose Cooling Tower fill?

What is the fill in a cooling tower?

The cooling tower is a cooling device, which makes the hot water in the tower be cooled mainly by the evaporative cooling of water. In order to make full use of water resources, reduce the load of urban tap water supply network, and reduce the operating cost, cooling water is treated by cooling tower and recycled.

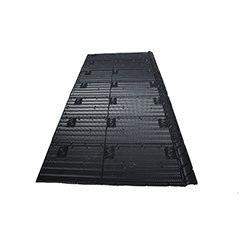

"Fill" is a medium that used in cooling towers to increase the surface area available for the water.

In a cooling tower, the really important actually is cooling tower fill. Fill is a plastic sheet used in cooling towers to build the more surface region of the tower. If we want to expanded surface, we need to take considers into making more contact about water and fills, so that water will have more surface area in the cooling tower fill.

Cooling tower fills make hot water have much more surface area with sheet and air and the medium of tremendously extended film fill, so that hot water is cooled quickly.

After be cooled the water is flow in a water container from which it is pumped again to cooling other hot water, and the warm air leaving the fill and releasing from the above of the cooling towers, and like this Continuously cooling air from bottom and release warm air from above to keep cooling tower cooling hot water continuously, to reduce the load of urban tap water supply network, and reduce the operating cost, So that we could make full use of water resources.

Filler is the most important part of the cooling tower, and its efficiency depends on the extent to which the cooling water and air are fully in contact with the filler. Filler temperature 50 °C ~ 68 °C, anti-aging, excellent performance, anti-ultraviolet, long life.

Cooling tower fill should be made to have more contact about water and fills, and longest time as possible. Fill allows the water to form thin flowing sheets to expose as much water surface area as possible to the interacting flow.

"Fill" is a medium that used in cooling towers to increase the surface area available for the water.

In a cooling tower, the really important actually is cooling tower fill. Fill is a plastic sheet used in cooling towers to build the more surface region of the tower. If we want to expanded surface, we need to take considers into making more contact about water and fills, so that water will have more surface area in the cooling tower fill.

Cooling tower fills make hot water have much more surface area with sheet and air and the medium of tremendously extended film fill, so that hot water is cooled quickly.

After be cooled the water is flow in a water container from which it is pumped again to cooling other hot water, and the warm air leaving the fill and releasing from the above of the cooling towers, and like this Continuously cooling air from bottom and release warm air from above to keep cooling tower cooling hot water continuously, to reduce the load of urban tap water supply network, and reduce the operating cost, So that we could make full use of water resources.

Filler is the most important part of the cooling tower, and its efficiency depends on the extent to which the cooling water and air are fully in contact with the filler. Filler temperature 50 °C ~ 68 °C, anti-aging, excellent performance, anti-ultraviolet, long life.

Cooling tower fill should be made to have more contact about water and fills, and longest time as possible. Fill allows the water to form thin flowing sheets to expose as much water surface area as possible to the interacting flow.

Types of cooling tower fills.

A cooling tower's performance is determined by many factors, cooling tower fills is one of the most import and parts a cooling tower, its types and quality decide whether a cooling tower could transfer heat efficiently or not. If you choose right type of cooling tower fill, water will flowing much more surface area, hot water will be cooled quickly.

There are two common types of fill media, splash fill and film fill. But what's the difference between the two? So, how do you choose the best one for increase efficiency and optimal performance?

♦ Splash Fill

Splash fill consists of layers of horizontal bars or slats. When the warm water hits the surface of these bars, it spreads, breaks, and forms small droplets. As more droplets are formed, there is increased contact between air and water, which accelerates the rate of cooling and evaporation.

Splash fill media were traditionally made from wood, but modern designs make use of PVC. PVC is more efficient as it facilitates better heat transfer.

Splash fill is ideal for use in industries which generate poor quality or dirty water. As the water is broken up to form small droplets, there is no medium in which dirt and debris can be caught and trapped; therefore, the efficiency of the medium is not reduced.

♦ Film Fill

Film fill consists of closely placed thin sheets of PVC material with a flat, corrugated or otherwise textured surface. It creates a large surface area on which the hot recirculated water spreads forming a thin film in contact with air. It allows heat to evaporate at an accelerated rate and cools the water faster.

Film fill is ideal for cooling clean and quality water, as any debris in the water can build up in the film media and reduce its efficiency and overall performance of the cooling tower. However, you can get a film fill with wider flutes if your water is not clean.

There are two common types of fill media, splash fill and film fill. But what's the difference between the two? So, how do you choose the best one for increase efficiency and optimal performance?

♦ Splash Fill

Splash fill consists of layers of horizontal bars or slats. When the warm water hits the surface of these bars, it spreads, breaks, and forms small droplets. As more droplets are formed, there is increased contact between air and water, which accelerates the rate of cooling and evaporation.

Splash fill media were traditionally made from wood, but modern designs make use of PVC. PVC is more efficient as it facilitates better heat transfer.

Splash fill is ideal for use in industries which generate poor quality or dirty water. As the water is broken up to form small droplets, there is no medium in which dirt and debris can be caught and trapped; therefore, the efficiency of the medium is not reduced.

♦ Film Fill

Film fill consists of closely placed thin sheets of PVC material with a flat, corrugated or otherwise textured surface. It creates a large surface area on which the hot recirculated water spreads forming a thin film in contact with air. It allows heat to evaporate at an accelerated rate and cools the water faster.

Film fill is ideal for cooling clean and quality water, as any debris in the water can build up in the film media and reduce its efficiency and overall performance of the cooling tower. However, you can get a film fill with wider flutes if your water is not clean.

Cooling tower fill function

The function of cooling tower fill is to increase heat dissipation,prolong residence time of cooling water, increase heat transfer area, increase heat transfer and distribute water evenly.

Cooling tower fillprovides sheets of material that are shaped into a corrugated pattern for the water to travel across. It can be combined and stacked into blocks, to create various thicknesses and heights to fit individual cooling towers.

Cooling tower fillprovides sheets of material that are shaped into a corrugated pattern for the water to travel across. It can be combined and stacked into blocks, to create various thicknesses and heights to fit individual cooling towers.

Cooling Tower Fill Principles of Operation

The application of pp film fill is to cooling hot waste. The fill is sheet type, so water flowing have much more surface area. hot water will be cooled quickly. This is the reason people use film fill proverbially. The principles of operation is:

Cooling tower fill makes hot water have much more surface area with sheet and air and the medium of tremendously extended film fill, so that hot water is cooled quickly. After be cooled the water is flow in a water container from which it is pumped again to cooling other hot water, and the warm air leaving the fill and releasing from the above of the cooling towers, and like this continuously cooling air from bottom and release warm air from above to keep cooling tower cooling hot water continuously.

The waste heat produced in industrial production or refrigeration process is generally driven away by cooling water. The cooling tower functions as heat exchange between the cooling water carrying waste heat and air in the tower.

Cooling tower fill makes hot water have much more surface area with sheet and air and the medium of tremendously extended film fill, so that hot water is cooled quickly. After be cooled the water is flow in a water container from which it is pumped again to cooling other hot water, and the warm air leaving the fill and releasing from the above of the cooling towers, and like this continuously cooling air from bottom and release warm air from above to keep cooling tower cooling hot water continuously.

The waste heat produced in industrial production or refrigeration process is generally driven away by cooling water. The cooling tower functions as heat exchange between the cooling water carrying waste heat and air in the tower.

What is the purpose of fill in a cooling tower?

The purpose of fill in a cooling tower is to cool water to make full use of water resources, reduce the load of urban tap water supply network, and reduce the operating cost, cooling water is treated by cooling tower and recycled.

Matters needing attention when replacing the cooling tower packing.

♦ The waveforms between the monolithic and the monolithic must be diagonally staggered so that they have good thermal resistance.

♦ The cuboidal packing assembly unit is most suitable for matching with the square tower and with the circumference of the circular cooling tower. A gap will be formed, and it needs to be filled with a different number of single sheets according to the size of the gap.

♦ Once the plug is blocked, it is not easy to clean. When the jam is serious, it needs to be replaced as a whole and it will increase the cost.

Matters needing attention when replacing the cooling tower packing.

♦ The waveforms between the monolithic and the monolithic must be diagonally staggered so that they have good thermal resistance.

♦ The cuboidal packing assembly unit is most suitable for matching with the square tower and with the circumference of the circular cooling tower. A gap will be formed, and it needs to be filled with a different number of single sheets according to the size of the gap.

♦ Once the plug is blocked, it is not easy to clean. When the jam is serious, it needs to be replaced as a whole and it will increase the cost.

How to choose Cooling Tower fill?

Both splash and film fill are ideal for facilitating the evaporation and cooling process in a cooling tower. However, film fill media is more efficient in heat transfer as it creates a larger surface area, hence optimized performance. However, it is more susceptible to wear and tear due to constant exposure to water at very high temperatures.

If your cooling tower applications involve recirculating water with poor quality and high solids content, you may opt for splash fill media for better performance. Also, if water is generated at very high temperatures, you may consider splash fill media with metallic bars as film fill media will wear away prematurely.

Cooling towers are essential equipment in most manufacturing industries. With this knowledge, you can choose the right type of tower fill media for optimal performance and improved efficiency of your industry's cooling tower.

The cooling tower is the main core of heat dissipation for circulating water in industrial production. In China's industrial production, it affects the cost and efficiency of industrial production in China.

Inappropriate use of cooling towers in industrial production can result in inefficient heat dissipation, production stagnation, and high water temperature risk. Cooling tower packing is the main factor that promotes hydrothermal cycle. Therefore, we must choose high-quality cooling tower packing.

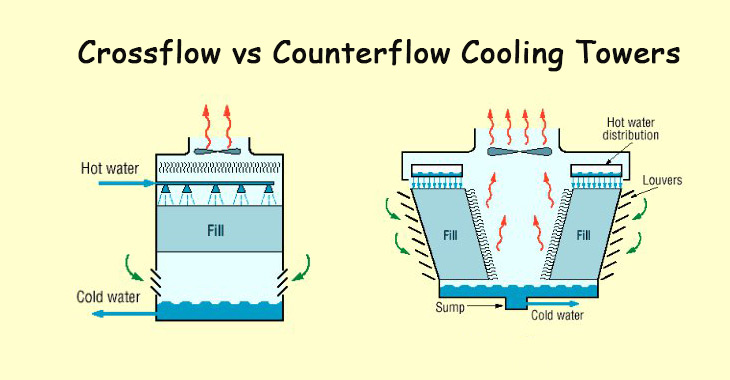

♦ First, the cross-flow cooling tower standard size.

The distance between the top of the cooling tower packing and the bottom of the fan should be 1.2 times the diameter of the fan.

♦ Second, counterflow cooling tower standard angle.

1. When constructing a counterflow cooling tower, the top of the packing and the airflow section should be controlled within 90 degrees. A flat top cover is used and a diversion coil is installed. The water eliminator and the airflow section are angled at 90-120 degrees.

2. Shrink-type tower top, the top corner of the shrinkage section cover should be controlled between 90-110 degrees.

3. The water filling angle is controlled between 5-8 degrees.

4. In the process of use, spare circulation measures should be set in order to prevent short circuit between the air and the bottom of the packing.

In cold regions, we must choose a special filler material, according to the local temperature is determined, select the filler with high cold resistance. The heat and resistance of the cooling tower packing should be based on comprehensive analysis of the fan. Through the calculation, design a suitable cooling tower packing.

If your cooling tower applications involve recirculating water with poor quality and high solids content, you may opt for splash fill media for better performance. Also, if water is generated at very high temperatures, you may consider splash fill media with metallic bars as film fill media will wear away prematurely.

Cooling towers are essential equipment in most manufacturing industries. With this knowledge, you can choose the right type of tower fill media for optimal performance and improved efficiency of your industry's cooling tower.

The cooling tower is the main core of heat dissipation for circulating water in industrial production. In China's industrial production, it affects the cost and efficiency of industrial production in China.

Inappropriate use of cooling towers in industrial production can result in inefficient heat dissipation, production stagnation, and high water temperature risk. Cooling tower packing is the main factor that promotes hydrothermal cycle. Therefore, we must choose high-quality cooling tower packing.

♦ First, the cross-flow cooling tower standard size.

The distance between the top of the cooling tower packing and the bottom of the fan should be 1.2 times the diameter of the fan.

♦ Second, counterflow cooling tower standard angle.

1. When constructing a counterflow cooling tower, the top of the packing and the airflow section should be controlled within 90 degrees. A flat top cover is used and a diversion coil is installed. The water eliminator and the airflow section are angled at 90-120 degrees.

2. Shrink-type tower top, the top corner of the shrinkage section cover should be controlled between 90-110 degrees.

3. The water filling angle is controlled between 5-8 degrees.

4. In the process of use, spare circulation measures should be set in order to prevent short circuit between the air and the bottom of the packing.

In cold regions, we must choose a special filler material, according to the local temperature is determined, select the filler with high cold resistance. The heat and resistance of the cooling tower packing should be based on comprehensive analysis of the fan. Through the calculation, design a suitable cooling tower packing.

You might also like

Categories

Trending