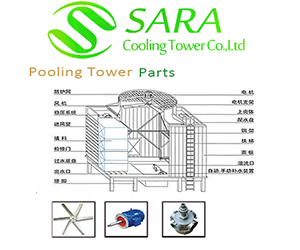

How to Assembly FRP Cooling Towers

Table of Contents

• Frp cooling tower body installation

• Frp cooling tower parts installation

• Water distribution device installatio

• Ventilation equipment installation

Here's how...

Section 1

Installation requirements

The installation of frp cooling tower shall be based on various conditions of the equipment, taking into consideration of ground and its load capacity at the installation location, and must also take into account the necessary external conditions.Installation frp cooling tower should pay attention to the foundation of the cooling tower, in accordance with the provisions of the size of pre-embedded horizontal steel plate, and elevation of each base point should be at the same elevation level.

Placed frp cooling tower horizontally. When the water tower is installed, in order to prevent the chassis from being crushed, the construction personnel should step on the ribs of the chassis.

Section 2

Frp cooling tower body installation

Frp cooling tower be installed in a well-ventilated place. Otherwise it will reduce the cooling tower's cooling capacity. The water pump takes the cooling water that needs to be processed from the water tank and sends it to the cooling tower. After being cooled, the water flows from the bottom water collecting tray down into the condenser and flows into the condenser downwards.

When installing, the position of the coordinate indicated in the construction drawing shall be in place, and the alignment shall be straightened. The equipment shall be stable and firm, and the direction and position of the outlet pipe and cooling tower nozzle shall be correct.

Section 3

Frp Cooling tower parts installation

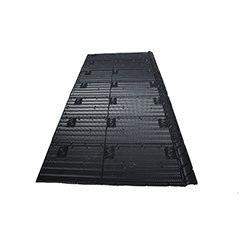

Installation of cooling tower parts. Cooling tower fills have different types such as diaphragm type, paper honeycomb type, dot wave type and ramp pattern type.

1) Cooling tower fills are generally made of plastic sheet. Each four pieces are joined together. The plates are separated by a plastic tube and a rubber gasket to form a certain gap, and the middle is fixed by galvanized bolts.

2) The paper honeycomb watering device can be directly mounted on angle steel or flat steel brackets, and can also be directly placed on small concrete brackets.

3) The unit height of the spot wave watering device is 150-600mm, and the small wave is generally 250ram. The total installation height is: 500 to 1200 mm when a counter-flow tower is used, and 1000 to 1500 mm when a cross-flow tower is used.

The commonly used mounting methods are frame threading and bonding methods:

Frame threading method The diameter of 4 copper wire or galvanized lead wire is used for positive and negative transmission of point wave plates to form a whole, which is assembled into a frame made of L 25×4 angle steel, and the frame is used as a mounting unit.

The bonding method is to use G52-2 perchloroethylene varnish, bond 40 to 50 pieces, and use a heavy object to press 1 ~ 1-5h.The adhesive unit is directly mounted on the support frame or the support beam.

4)The unit height of diagonal ripple water spraying device is 300-400mm. Its installation height is 800-1200mm.

Section 4

Water distribution device installation

There are two kinds of water distribution devices: fixed tube water distributor and rotary tube water distributor.

The cooling tower nozzles should meet the technical conditions or design requirements of the equipment. In general, the distance between the nozzles is determined according to the spray angle and the installed height, so that the water droplets of each nozzle cross each other and the water is evenly distributed to the water spraying device.

There are the following three types of installations for cooling tower nozzle or water distributor:

♦ Assemble the water distribution pipe with slits. The width of the seam is generally 2-3nvn, and the seams are arranged horizontally.

♦ Nozzle water distribution, installation according to equipment technical conditions or design requirements.

♦ The water distribution pipe with a round hole is equipped with a hole diameter of 3-6mm and a hole distance of 8-16mm. When installing in a single row, the angle between the hole and the horizontal direction is 30. Double-row installation when the upper row of holes and the horizontal angle of 60. , The angle between the bottom row of holes and the horizontal direction is 45. The opening area is 50% to 60% of the total cross-sectional area of the water distribution pipe.

Section 5

Ventilation equipment installation

According to frp cooling towers, there are two kinds of ventilation equipment: ventilation type and blast type:

♦ An exhaust cooling tower should be used. The motor cover and rotor should have good waterproofing measures. Enclosed squirrel-cage motors are usually used, and the terminals are sealed with rosin or other sealing insulation.

♦ Using a forced-air cooling tower, the distance between the fan and the cooling tower body should not be less than 2m in order to prevent the fan from splashing.

Section 6

Receiver installation

The water closet is generally installed on the water distribution pipe, in the water distribution tank or above the tank, and retains the water droplets discharged from the air outside the tower, which acts as a separation between the water drop and the air. In the draft cooling tower, the water eliminator and the fan should maintain a certain distance to prevent eddy currents from increasing the resistance and reduce the cooling effect.

You might also like

Categories

Trending