US $1.50-$3.00 / Piece

Cooling towers are heat rejection devices which reject waste heat to the atmosphere via the cooling of a water stream in order to lower temperature.

And if you have never worked in a cooling tower before then you might think that the heart of any cooling towers is the water itself. Although the main purpose of any cooling tower does revolve around water, the true heart of every cooling tower is its fills. We can help get different pvc fills for cooling tower.

Cooling tower fills also known as the surface or the wet deck is a medium that utilizes parts of the cooling tower in order to build its surface region. An extended surface territory considers the most extreme contact between the water and air which takes more prominent dissipation rates.

A PVC fill will give an extended water-air interface for the warming of air vanishing occurs. The water will be cooled as it slides through the fill with gravity. The cooled water is then gathered in a frosty water bowl under the fill from which it will be pumped again through the same process to assimilate more high temperature.

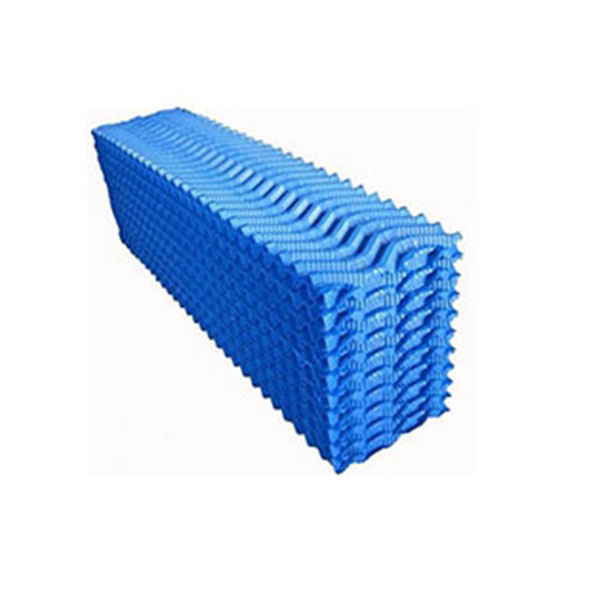

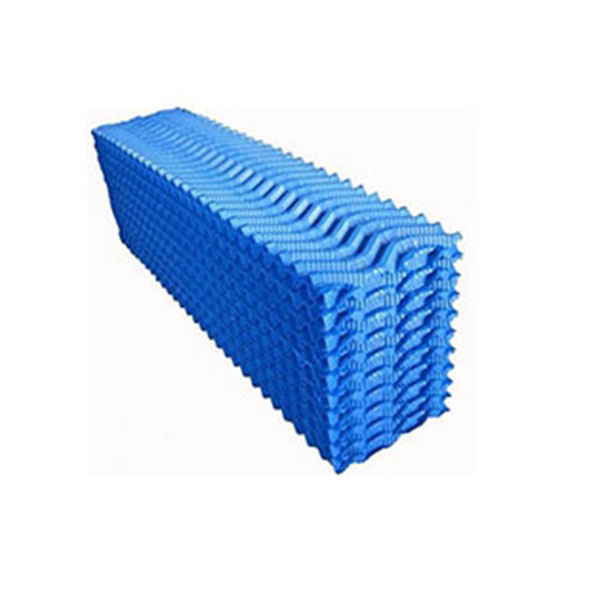

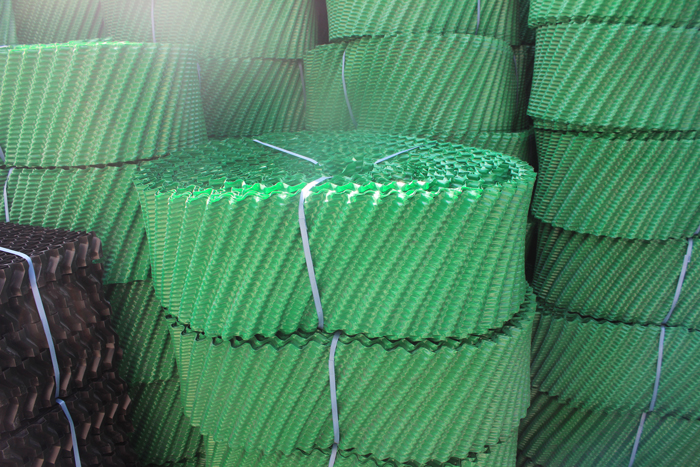

Our PVC Fills for cooling towers are made of corrugated high-quality PVC films that are edge-folded and vacuum formed for extended service life. Its edge folded technology can help reduce the erosion of the fills and can save the equipment from damages, thus ensuring a longer service life.

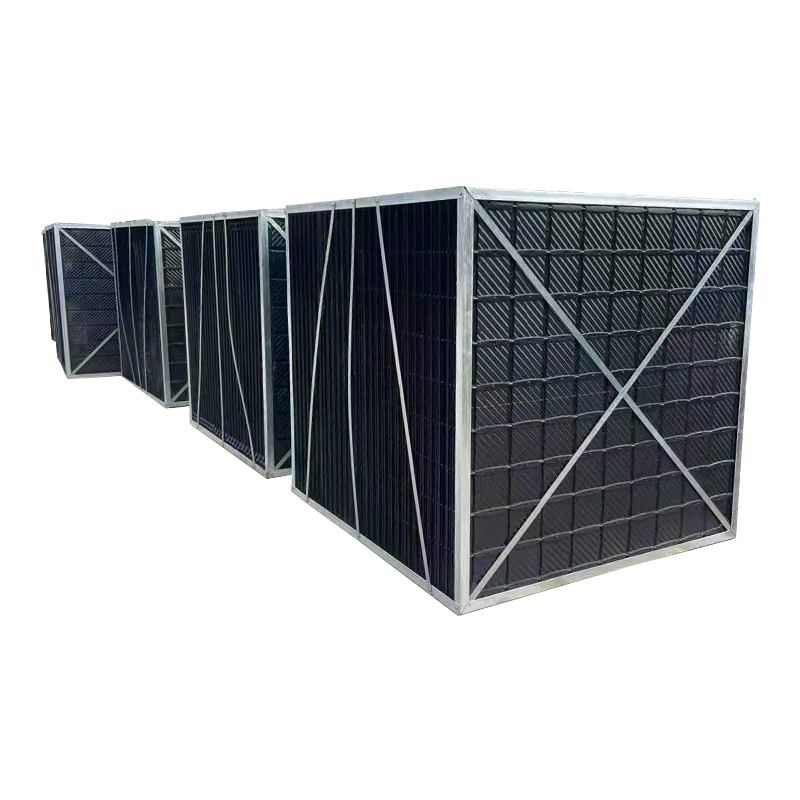

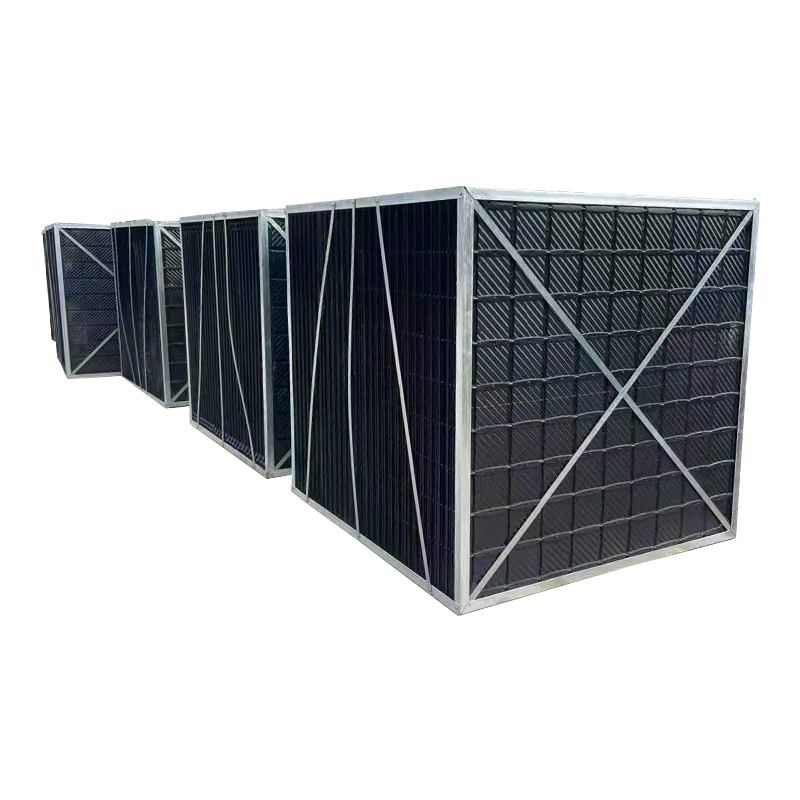

Available in black and blue colors, our PVC Fills for cooling towers is FRP induced draft for cross-flow type and counterflow type. Our PVC fills are also made of continuous forming and offer minimum resistance to airflow, thus providing more cooling and lowering power consumptions.

We guarantee that our PVC are durable, providing strength at critical locations and have a uniform thickness. Our PVC fills are very easy to glue at the site and install, therefore saves transportation costs.

S Wave Filler

Green Round Fill

Black Round Fills

PVC Filler

The structure of an S-W PVC filler is simple and unique that supports large hydrophilic area and offers a good cooling effect. It is lightweight, high resistance to chemical corrosions, good flame retardancy, easy to install, high cooling efficiency and has a wide application scope.

This PVC fill is mainly used for hyperbolic cement cooling tower of power plants and industrial countercurrent cooling towers.

| S Wave PVC fillers | |||

| Length | Width | Thickness | Suitable Temperature |

| 1000 mm or can be customized | 500 mm/800 to 1400 mm | 0.3 to 0.6 mm | -35 to 65 degrees Celsius |

Our Oblique PVC fills are lightweight, high corrosion resistance, good strength, advanced design, low ventilation resistance, good flame retardancy and have a strong hydrophilicity. Also, it has a large contact area and suitable for hyperbolic cooling towers and square counterflow cooling towers.

| Oblique PVC Fillers | ||||

| Length | Width | Sheet Height | Thickness | Suitable Temperature |

| Customized | 300 mm / 600 mm | 12 mm / 15 mm / 19mm | 0.25 to 0.4 mm | -35 to 65 degrees Celsius |

Our Round PVC Fillers adopt the most current technology. Our Round PVC fillers are extremely durable and it has a good cooling effect. Also, it offers a strong hydrophilicity and has a large contact area. Round PVC fills are most commonly used for a circular countercurrent cooling tower.

| Round PVC Fillers | ||||

| Length | Width | Sheet Space | Depth | Flute angle |

| 4 ft (1220 mm),6 ft (1829 mm),8 ft (2439 mm) or 10 ft (3048 mm) | 12 in (305 mm) or 24 in (610 mm) | 19 mm | 12 in (305 mm) or 24 in (610 mm) | 30° |

Excellent heat transfer

Accurate Dimensions

Simple Installations

High Durability

Excellent finish

Good Chemical Stability

The application range of cooling tower PVC fills is:

Industrial water cooling

Air compressor

Aluminum profile processing

Steam turbine

Power generation

Tannery

Electric furnace

Freezing Series

Air conditioning cooling system

A. As I’ve mentioned earlier, PVC fills are the heart of any cooling tower. This is because it is responsible for the increase of circulation water surface area that is exposed to the airflow and significantly boost heat rejection and help reduce air resistance.

A counterflow or crossflow designation is the orientation of airflow within the PVC fill in the cooling tower to the direction of the water flow.

In a crossflow, the air passes through the PVC fill media in a horizontal direction, therefore crossing a downward waterfall. Counterflow, on the other hand, that air travels upwards vertically through the PVC fill and makes contact with the water droplets that are falling down through the PVC fill media. Thus, the water and air travel in opposite directions.

Generally, a counterflow cooling tower is said to be more efficient than crossflow cooling towers.

A. There are 2 basic types of fills used in a cooling tower: the film-type and the splash-type. Either type os fills can be used in cooling towers of both counterflow and crossflow configurations.

Film-type fills have gain dominance in the cooling tower industry because of its ability t expose a greater water surface within a given packed volume. Its key features include:

Greater cooling capacity in a particular space

Single-piece, full height counterflow designs

High-temperature designs

Counterflow and crossflow design

Available in hanging or bottom supported designs

Low clog designs

Splash-type fills, on the other hand, causes the flowing water to cascade through a successive elevations of parallel "splash bars". Its key features include:

Ideal for "dirty water" applications

Water is easily distributed

Far more forgiving of a poor water distribution caused by missing nozzles and clogs

Easy maintenance

Ideal for wooden or dusty environments

Long service life

Heavy ice loads design

High temperature designs

Many PVC fills in our factory

PVC fills are loaded by our workers

PVC fills are shipped by trucks

If you are looking for high quality PVC fills for cooling towers, then you do not need to search anymore. As a good pvc fill for cooling tower suppliers, we provide you with only the best quality cooling tower fills and services. We guarantee that the PVC fills we offer are only durable and provides high efficiency.

Copyright © 2018 SARACOOLINGTOWER - All Rights Reserved